Dual Robots With A Vision System

Innovate Engineering & Design, incorporating a second robot, a vision system and a level detecting laser into its automated compound collection system vastly improves the performance of its NovaCCS™. In many cases the enhanced NovaCCS™ completed compound transfers in 3 minutes or less equating to approximately160 transfers per 8 hour shift. In the following tables, the improved performance will be demonstrated.

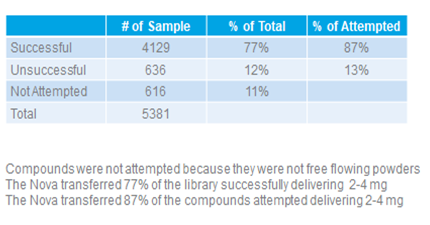

Results from an initial study conducted by a client using the single robot Nova are shown in the first two tables. These results were presented at the Compound Management & Integrity 2012 Conference. A synopsis of the conference can be seen HERE.

The initial study incumpased 5381 compounds that had been pulled from mass storage to fulfill orders sent from labs. The first step of that study was to quickly visually inspect compounds to determine their consistancy and whether they were free flowing powders or liquids, tares or chuncks. Of the 5381 selected, 616 were determined to be either a liquid, a tare or large chuncks which were not compatible with the Nova system. The 616 compounds were removed from the study.

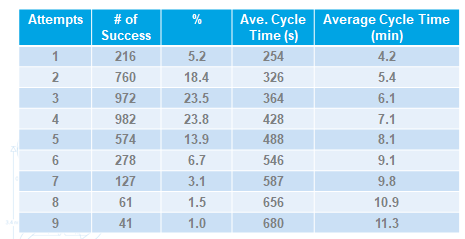

The following chart gives a breakdown of the number of successful transfers and the number of attempts required to complete them. Keep in mind that not all collection attempts result in a transfer of compound into the destination container. A completed transfer may have required 5 collection attempts but perhaps only two meet the weight criteria that would have resulted in a transfer. Collection attempts may result in too much or too little but still count as an attempt. Only those collection attempts meeting the weight criteria will result in a transfer. Note 1: Also, these numbers are not inclusive of the total study as the results for more than 9 attempts were extremely minor in comparison to those shown. Note 2:If you are not familiar with the concept of an attempt, please watch videos.

Using results of the initial study which used the single robot system, we will compare the cycle times between the two robot system verses the single robot system.Using the data from the initial study which used the single robot system, the charts below demonstrate the time savings that are possible with the addition of the second robot and vision system. NOTE: The number of samples processed using the dual robot and vision system is considerably less than the 4700 processed using the conventional single robot NovaCCS .

The first table shows the time savings

for successful transfers. As much as two three times faster.

While the second table shows the time savings that can be attained with unsuccessful collections.

|

Number of Collection Attempts Having To Be Made To Complete The Successful Transfer |

Average Time in Minutes To Complete Transfers Using Scale Process and Single Robot |

Average Time in Minutes To Complete Transfers Using Dual Robot and Vision |

|

1 |

4.2 |

1.7 |

|

2 |

5.4 |

2.5 |

|

3 |

6.1 |

2.5 |

|

4 |

7.1 |

2.4 |

|

5 |

8.1 |

3.4 |

Number of Attempts Made Before Transfer Was Determined To Be

Unsuccessful

Average Cycle Time in Minutes Using Scale Process and Single Robot

Average Cycle Time in Minutes With Vision System and Dual Robots

5

6.3

1.4

As can be seen, adding the second robot and a vision system dramatically

reduces the time consumed by the Nova’s major time consuming facets,

stabilization of scales and the capping/decapping

process. While the actual collection process only takes a minute or two, scale stabilization

and capping/decapping can double, triple or more the

amount of time spent on the completed transfer.